How to join air tightness membranes

Learning how to join air tightness membranes is a simple enough job and one that needs to be done correctly so that you get the most out of your materials.

In the realm of modern construction and energy-efficient building practices, airtightness membranes have emerged as essential components for creating energy-efficient and comfortable structures. However, achieving a high level of airtightness requires meticulous attention to detail, especially when it comes to joining membranes. So lets take a look at the techniques and considerations involved in how to join airtightness membranes to ensure optimal building performance.

Understanding Airtightness Membranes

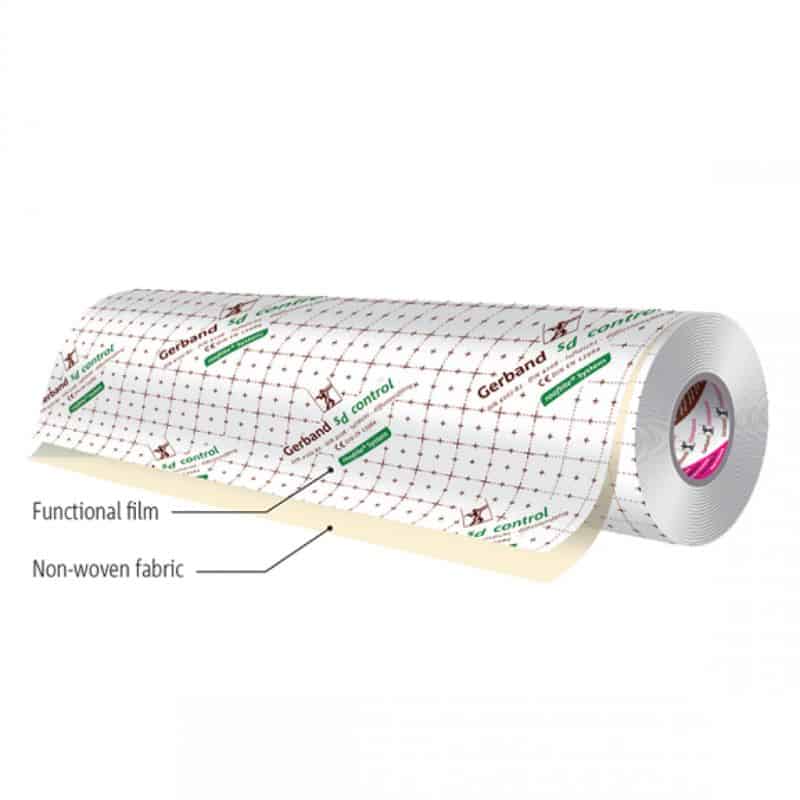

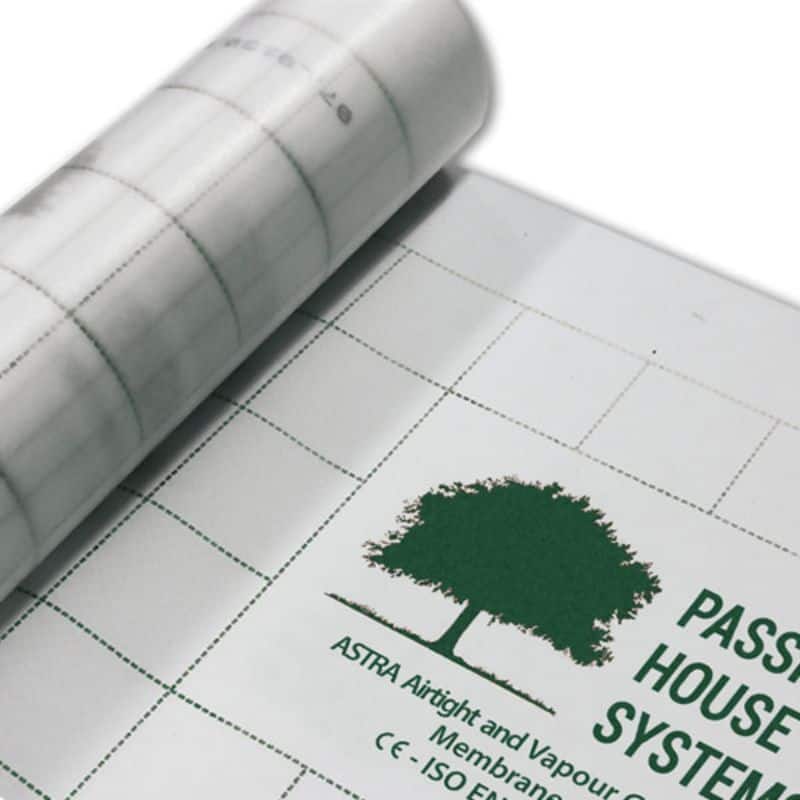

Airtightness membranes, also known as vapor control layers or air barriers, are materials designed to prevent the unwanted exchange of air between the interior and exterior of a building. These membranes play a crucial role in maintaining energy efficiency, preventing moisture infiltration, and improving indoor air quality.

Choosing the Right Membrane

Before considering looking at how to join air tightness membranes, it’s important to select the appropriate airtightness membrane for your specific application. Factors to consider include:

- Material Type: Airtightness membranes come in various materials, such as polyethylene, polypropylene, and composite films. Choose a material that aligns with your project’s requirements, taking into account factors like flexibility, durability, and compatibility with other building components.

- Permeability: Membranes vary in their vapor permeability levels. Ensure that the chosen membrane’s permeability aligns with your climate and the desired moisture management strategy.

- Adhesive Properties: Some membranes have built-in adhesives, simplifying the joining process. Others may require separate adhesive products.

How to join air tightness membranes:

- Lap Joints: This is a common method where one membrane overlaps another. Ensure that the upper layer overlaps the lower one to prevent water ingress. Secure the overlap using compatible adhesive tape designed for airtightness applications.

- Taped Joints: Specialized airtight adhesive tapes are used to create airtight and waterproof seals between membrane sections. These tapes often have high adhesion properties and are designed to work effectively with the chosen membrane material.

- Welding or Heat Sealing: In some cases, membranes can be heat-sealed together using specialized equipment. This method provides a permanent and robust airtight joint. It’s crucial to follow manufacturer guidelines for temperature and pressure settings.

- Air Tightness Sealant: This sealant creates a bond between the membranes and this sealant works very well.

- Mechanical Fasteners: In areas where membranes may be under stress or require extra reinforcement, mechanical fasteners can be used in conjunction with adhesive tapes to create secure joints.

Step-by-Step Process for how to join air tightness membranes:

- Prepare the Surface: Ensure the surfaces where the membranes will be joined are clean, dry, and free of debris or contaminants.

- Position the Membranes: Align the membranes accurately, ensuring proper overlap or alignment as required.

- Apply Adhesive: If using adhesive tapes, carefully apply the tape along the joint, following manufacturer recommendations for application technique.

- Secure and Press: Gently press down on the tape to ensure a strong bond. Use a roller or your hand to smooth out any air bubbles or wrinkles that could compromise the airtight seal.

- Inspect and Test: After joining, visually inspect the joint for proper adhesion and alignment. Consider conducting a blower door test to assess the overall airtightness of the building envelope.

Joining airtightness membranes is a critical step in creating a high-performance building envelope that contributes to energy efficiency, comfort, and durability. By selecting the right membrane, adhering to recommended joining techniques, and following proper installation procedures, you can ensure airtight seals that stand the test of time. Prioritising airtightness in construction not only leads to lower energy bills but also fosters healthier indoor environments and reduces a building’s environmental footprint.